When it comes to mattresses there really aren’t that many people that get very excited. So how cool could a mattress factory of all places really be? The answer…so, so, SO cool!

Earlier this week I had the opportunity to tour Brooklyn Bedding’s brand new state-of-the-art factory. Their new factory is located in the heart of Phoenix, Arizona. It is a whooping 145,000 square feet and cost $7,000,000 to construct. It is a BIG place.

Brooklyn Bedding manufactures some of the most popular and well-made mattresses across the US. They are most known for the design and manufacturing of their own brands, Brooklyn Bedding and DreamFoam. Their mattresses are primarily constructed from different types of latex foam, memory foam, polyfoam, and other types of foam.

Brooklyn Bedding and DreamFoam are among a very small number of online companies that actually own their mattress factory. This gives them a great degree of flexibility in terms of design, construction, materials, assembly, and of course offering the best price possible. There’s a lot that goes in to building a new mattress. Covers and other fabric pieces must be woven, cut, and sown together. Foams must be measured, cut, formed, and glued. And of course, all of the individual components must be assembled together into a final mattress before packing the entire thing into a box, ready to be shipped.

REVIEW: Check out our full review of the Brooklyn Bedding mattress

The tour through Brooklyn Bedding was an eye opener for me to be sure. Check out my complete video tour below or scroll below to take the visual tour and discover exactly how your new mattress is created and arrives at your doorstep.

Step 1, The Cover – The process begins with raw textiles. These are woven into what will become the top piece of fabric for the mattress cover.

Step 2, Cover Side Panels – A separate, but similar machine, weaves together the the side panel pieces. They are woven in a single sheet and cut, effectively creating about a dozen side panels at a time from a single roll (note the long cuts spread about 6 inches apart).

Step 3, Master Seamstresses – Once the cover pieces have been woven together by machines master seamstresses sew the pieces together by hand. It is insane how fast these ladies can move through a cover!

Step 4, Complete Top Cover – This is what a mattress top cover looks like. The thinner pieces of material hanging off the side of the cover will be used to sew the side panels together with the other assembly of the mattress.

Step 5, Support Foam – At the other end of the factory you’ll find the foam slicing machine. Massive blocks of foam, about 5 feet high, are sent through this machine. It measure the foam and slices the appropriate size off. The foam then travels down the line to the next step. (watch video above to see this machine in action!)

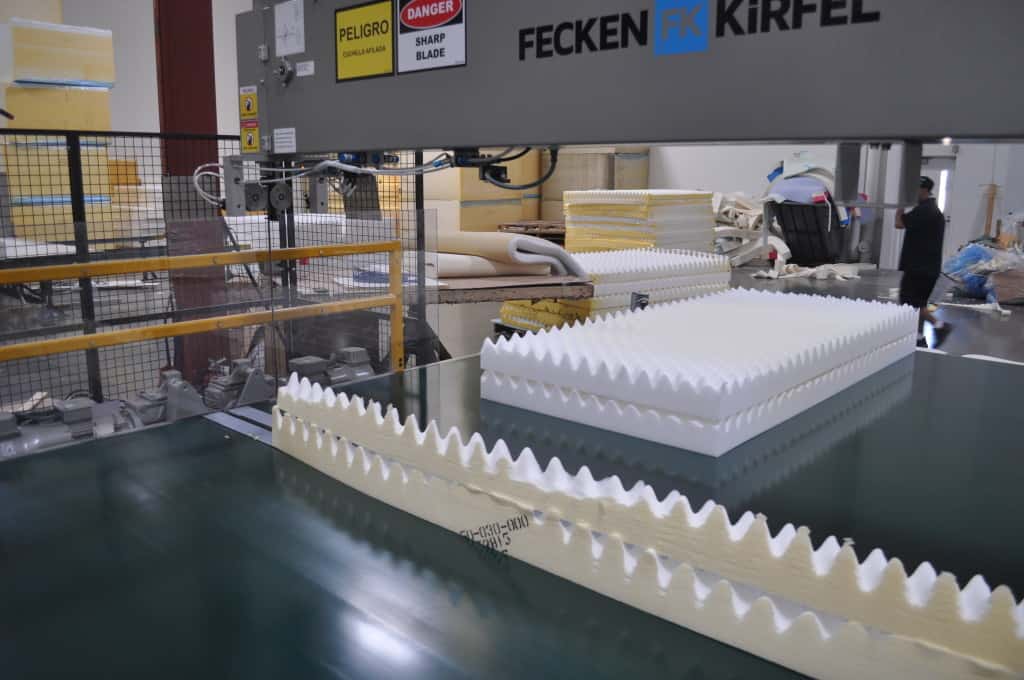

Step 6, Convoluted Foam Core – Next up on the foam line is the convoluted foam machine. It has rows of spinning teeth that cut the foam into 2 equal sections and carve in the convoluted channels. These foam channels allow for better deep compression support and breathability in the foam, improving cooling.

Step 7, Final Foam Cores – This is the end of the line with the completed convoluted support foam. Not pictured is the machine that applies a thin layer of glue. Additionally, after the glue is applied this particular mattress (it’s one of the DreamFoam mattresses) needs two foam layers stacked on top of each other. The machine at the very end here presses these layers together, ensuring they stay bonded permanently.

Step 8, Foam Slicer – Once the foam cores are completed they are sent to the cutting station. This machine cuts any excess from the foam, ensuring it is sized appropriately for the mattress it’s going into. Even with an insanely sharp blade and something as easy to cut as foam, the blades must be replaced every 4 weeks due to the sheer volume of cutting. The excess foam is bailed and sold to other companies.

Step 8, Component Assembly – The completed foam cores and covers are brought to the primary assembly line (it sits in the middle of the factory). Workers sew and assemble the components together to form the completed mattress.

Step 9, Sewing Everything Together – One of the most skilled positions on the factory floor are the workers who sew the completed cover and side panels together within the foam structure. There is very little room for error. Massive industrial sewing machines rotate around the perimeter of the mattress (they sit on a rail type of a system). Havier (pictured in the white shirt in the middle), is an artisan when it comes to this work. He’s been working with Brooklyn Bedding since they created their first mattress in 2001.

Step 10, Compressed for Shipping – Once the mattresses are completely assembled they are sent to the 1 of 4 roll packing machines. The simpler machines cost $125,000. This advanced roll packer is $400,000 and compresses the mattress both on the sides and top before final vacuum sealing it. This allows a King mattress to fix into a 19 x 19 x 45 inch box.

Step 11, Enjoy – That’s it! Mattresses are shipped all across the country. Below is their newest mattress, the Brooklyn Bedding mattress uncompressed and on my King sized platform bed.

Hi Sleepopolis, Love your site. Bought am Americana by Amerisleep as we were looking for firm but are unhappy with the edge support. Would the firm version of the Brooklyn Bedding give us better edge support and similar, of not more firm, comfort overall. My wife and I both like it plenty firm. Thanks.

Hi Drew,

My apologies for the slow reply to this. I got super backed up on comments / emails over the holidays and I’m just now catching up.

To answer your question, I would not advise the BB if you’re concerned about edge support. The BB firm is not substantially different than the Americana with respect to edge support.

Unfortunately, edge support on foam mattresses just isn’t that great. Even when it’s good, it’s still not as good as a coil mattress. If edge support is critical I would suggest you take a look at the Sapira, Saatva, or Winkbeds mattresses. The coil / hybrid design of those beds creates much better edge support.

Hi Sleepopolis.

I had a chance to visit R&S Mattress retail shop in Tempe AZ.

They carry huge selection of Brooklyn mattresses not just latex foam.

I really liked one of memory foam mattress however i would not be able to find any information about it’s foam layers not even on their R&S site. Sales person said 3 layers of 5lb memory foam but e-mail that I have got from corporate was 4 layers without knowing the density of foam.

Since you have visited their factory, would i be able to trust the quality of layers that they use?

or should i just stick with online mattress shopping such as leesa or tuft & needle?

Their price for 12″ queen size memory foam was $799 with a box spring. Just not sure about quality with that price point.

The only risk to buying one from the physical R&S store is the trial period. I do trust Brooklyn Bedding, but I don’t trust that the feel that I think I like in-store is the same as I’m going to experience the mattress in-home. That’s why the trial period and easy return / refund policy is so important.

For this reason I’d stick with an online mattress.

Hi Sleepopolis,

My husband and I are in the market for a new mattress and quite by accident I came across your excellent website. We really appreciate the thoroughness and unbiased nature of your reviews.

We have narrowed our choices to about three mattresses so we are much closer to making a decision, thanks to your reviews!

Keep up the great work!

Thanks for your feedback, Sharon! I’m glad Sleepopolis has been helpful.

If you have any specific questions I can help with please don’t hesitate to let me know, or feel free to email me directly here https://sleepopolis.com/contact/

Sleepopolis,

Love the comparisons and the thorough reviews. What type of platform bed do you own? I like the sleek design.

Thanks,

Julie Cohen

Sacramento, CA.

Thanks for the kind words, Julie!

It’s called the Bellmar from Copenhagen Imports. More information here https://sleepopolis.com/blog/whats-the-sleepopolis-platform-bed-frame/

Hi – great article! where is the new factory located?

Thanks

Thank you! It’s located in Phoenix, Arizona.

Great Job….. Bedding Industries of America

After mulling over the other brands, I just bought a Brooklyn Bedding mattress today because of your helpful recommendations (don’t worry—made sure to use your promo code), and this article/video made me excited to retrieve it! Made in the U.S.A.! Thanks for your solid work, Sleepopolis.

#GOTeamUSA!

Thanks very much, Zack! The BB is a great mattress. I don’t think you’ll be disappointed. Let me know how you like it once it arrives.

Hi, Zack,

I sw your post here on Sleepopolis re: Brooklyn Bedding. I’m in the market for a new foam mattress and am in the research phase, considering Casper, Leesa, Tuft & Needle, and, now, BB. Since it’s been several months now, what are your thoughts on your BB purchase.

Thanks,

John

Didn’t realize what went into the manufacturing. Thanks for sharing this. My wife and I enjoy your website as we go through and research our mattress search. You do a great job!

Thanks for your kind words, Neil! I appreciate them.

It really is crazy how much goes into each mattress. It was a surprise to me as well.