Ever heard of the mattress manufacturer, Diamond? Diamond is one of the largest mattress makers in the US and has been in business for over 70 years. We’re about to take you inside their factory where all the magic happens.

Recently, Diamond branched out adding the Hyphen mattress as a sister company. Hyphen is still relatively new, but quickly making a name for themselves. Earlier this summer, Sleepopolis was on location in Los Angeles, California checking out Hyphen’s factory. Watch the short video below to see how the Hyphen comes together!

Hyphen Mattress Manufacturing Process

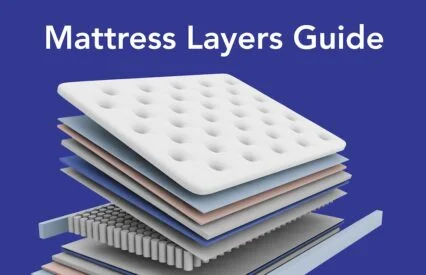

- Hyphen’s foams are delivered in large blocks, which are neatly stacked around their factory in visual kanbans (for you manufacturing aficionados) and used to create each Hyphen mattress.

- The process all begins with the cover. A seamstress takes the inside lining of the cover and quickly sews it to the outer piece of fabric.

- Large foam blocks are cut into smaller layers, allowing them to be glued and assembled.

- Once the foams are cut, they’re organized and individually put through a laminator / rolling glue machine. This lamentation machine puts a thin layer of glue on the foam.

- Next the foams go through an infrared oven, which helps remove water from the glue, helping it dry more quickly.

- Once the layers have all gone through the oven and are stacked on top of one another, they are placed into a compression machine, which then places pressure onto the foams to ensure all of them are securely glued together.

- After being removed from the compressor, the foams are placed into a fire sock and sealed off. Two team members at Hyphen push the mattress through the fire sock and use a large cutter to seal off the sock.

- Next up, the cover of the mattress is sewn / zipped on. In order to do so, the mattress is placed on a spinning table and an employee quickly spins the mattress while stretching the cover for a smooth fit around the foam layers.

- Now that we have a full Hyphen mattress made it’s time to compress the foams down. A large hydraulic machine compresses the foams both on top and the sides, before wrapping and rolling in plastic.

- Finally, the rolled mattress is placed in a box.

- The shipping label is placed on the box and immediately loaded onto the shipping carrier for delivery!

For more on the Hyphen mattress, check out our review series below:

If you’re looking for even more information visit HyphenSleep.com.